Predictive Maintenance (PdM) represents an innovative approach in the maintenance landscape, leveraging advanced technological tools to optimize equipment performance and extend their lifespan. By continuously monitoring the health of equipment in real-time, PdM enables timely detection and resolution of issues and allows the prediction of future states of equipment, thereby mitigating risk. The distinction lies in providing apt information at the right time to the right people.

The Evolution of Maintenance Strategies

Maintenance strategies have seen a significant evolution over the years, largely based on factors such as asset replacement cost, the criticality of assets, usage patterns and the potential impact of failure on safety, environment, operations and public image.

-

Maintenance maturity encompasses three leading strategies:

- Reactive Maintenance: It involves addressing failures when they occur, making it a purely responsive approach.

- Preventive Maintenance: This strategy is based on a predefined maintenance schedule aimed at identifying faults before they cause significant damage.

- Predictive Maintenance: Proactive in nature, PdM enhances preventive maintenance by providing continuous insights on the actual condition of the equipment rather than relying on the expected condition based on a historical baseline.

Predictive Maintenance: A Closer Look

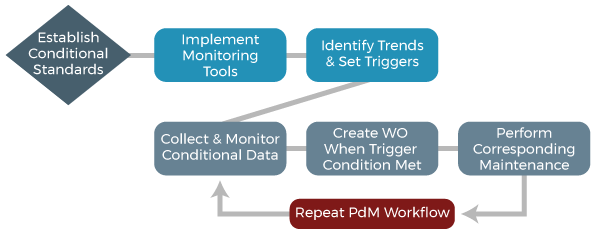

Predictive Maintenance utilizes historical and real-time data to predict the future potential health of equipment and anticipate problems in advance. This approach allows businesses to optimize maintenance scheduling and improve reliability. It differs from preventive maintenance in the diversity and breadth of real-time data used in monitoring the equipment. Various condition monitoring techniques such as sound (ultrasonic acoustics), temperature (thermal), lubrication (oil, fluids) and vibration analysis can identify anomalies and provide advance warnings of potential problems.

The Role of Technology in Predictive Maintenance

Predictive maintenance relies heavily on a variety of technologies, including the Internet of Things (IoT), predictive analytics and artificial intelligence (AI). Connected sensors gather data from assets such as machinery and equipment. This data is collected at the edge or in the cloud in an AI-enabled enterprise asset management (EAM) or computerized maintenance management system (CMMS). AI and machine learning are used to analyze the data in real-time to build a picture of the current condition of the equipment, triggering an alert if any potential defect is identified and delivering it to the maintenance team.

The Power of Predictive Maintenance

Benefits from a predictive maintenance strategy center around anticipating equipment faults and failures, reducing maintenance and operating costs by optimizing time and resources, and improving the performance and reliability of equipment. Deloitte reported in 2022 that PdM can result in a 5-15% reduction in facility downtime and a 5-20% increase in labor productivity.

Challenges in Implementing Predictive Maintenance

Despite the numerous benefits, implementing predictive maintenance can come with its own set of challenges. These include high startup costs associated with the complexity of the strategy, workforce training, and data requirements. These challenges, however, can be overcome with proper planning and execution and the benefits of a well-executed predictive maintenance strategy are immense.

Industry Use Cases of Predictive Maintenance

Predictive maintenance technologies are already being adopted across industries for many assets ranging from cash points, wind turbines, heat exchangers to manufacturing robots. Asset-intensive industries such as Energy, Manufacturing, Telecommunications and Transportation, where unforeseen equipment failures could have widespread consequences, are increasingly turning to advanced technologies to improve equipment reliability and labor force productivity.

Future of Predictive Maintenance

Technological advances in IoT sensors, big data collection, and storage technologies have and will continue to promote the adoption of predictive maintenance. The soaring cost of unplanned downtime, which experts estimate is around 11% of turnover in Fortune Global 500 companies, is also fueling the adoption of predictive maintenance within the market.

Conclusion

Predictive Maintenance represents a paradigm shift in the field of facility management, bringing about significant cost savings and enhancing the efficiency of operations. With the rise of AI, IoT, and machine learning technologies, the future of maintenance is set to be revolutionized, making facilities smarter, more efficient, and more sustainable.